Mining for ironsand is an undertaking of its own, and calls for a delicate collecting process before the arduous smelting can even begin. Most of the earth’s iron ore comes from sedimentary rock deposits formed nearly two billion years ago, which can be found most abundantly along coastlines and surrounding veins.

Iron ore is rather scarce in Japan, as the majority of its viable coastal deposits are submerged beneath the waves around the archipelago. Deep sea mining is a costly technology, both financially and ecologically, and would have of course been inaccessible to people centuries ago. In fact, mining iron ore from the seabed today would still cost considerably more than simply importing it from other countries, which Japan now does for much of its raw materials, including iron.

While Japan was lacking in regular iron ore deposits, there was one thing it had lots of: volcanoes. And luckily, ironsand is plentiful in areas with ancient volcanic rocks such as granite and basalt, which have been worn down into grains by millennia of erosion. Historical Japanese swordsmiths looked to ironsand as a sensible local alternative in the era before mass international commerce.

The area around Mt. Sentsuu in Izumo, for instance, was settled by communities of ironworkers for this very purpose. In fact, a local folkdance depicts the god Susanoo facing off against the eight-headed serpent Yamata no Orochi, whose body represented a flowing ironsand river, and whose slain corpse was forged into the legendary sword known as Kusanagi no Tsurugi.

View from atop Mt. Sentsuu in Izumo, Shimane. The base of the mountain has long been used for its ironsand-rich granite, formed from prehistoric magma flows. Between the mid 18th and 19th centuries, the vast majority of the iron and steel produced in Japan came from this area. The last remaining tamahagane furnace still in operation is located in nearby Okuizumo.

While most iron ore can simply be pulverized into smaller rock fragments for easy collecting and smelting, ironsand is loose and powdery, making extraction rather cumbersome, never mind the fact that it’s mixed in with other minerals. Consequently, a more convenient method of extraction was devised. Because the iron is heavier than the quartz, basalt, and other minerals, they can be separated from it through water filtration not too dissimilar from the method used in gold panning.

This process was relatively simple: miners could use devices such as rocker boxes or sluice boxes, which would catch iron particles in mesh basins as the sand-filled water washed through them. Such projects often called for the collective effort of large teams of ironworkers who would scour riverbeds and beaches where ironsand had collected, even installing artificial dredge systems which could be manipulated to filter out the iron grains.

Ironworkers near Sannai Village in Shimane filtering ironsand through a specialized water channel. Handheld paddles could be used to guide ironsand-rich water through filters which would separate the iron from lighter minerals.

Today, a more modern and convenient method of filtering ironsand is to use a magnet to simply attract the iron grains out of the mixture. This technique is faster and easier than using water filters.

After the iron from the mixture has been thoroughly collected, it now needs to be smelted into tamahagane. However, the iron was just the first ingredient, and it alone cannot be made into steel. For this, it needs to be mixed with a source of carbon, which will provide hardness and strength to the final product. The steel would simply not be able to hold itself together otherwise. Think of it as a binding agent - the eggs to the batter. You wouldn't want flaky, crumbly dough!

Fortunately, charcoal (sumi) makes for a great fuel and carbon source and is easy to acquire, unlike the ironsand. The two must now be combined and heated to a temperature of about 1,500 °F to 1,800 °F, about as hot as magma, using a special type of furnace called a tatara.

Charcoal can be made easily by burning wood, peat, and other carbon-dense materials. This is not to be confused with coal, which is a naturally occurring mineral.

Because iron in sand form is quite loose and messy, smelting it in a conventional blast furnace or bloomery is rather impractical. The tatara solves this issue by taking on a tub-like shape, wherein the ironsand will sink to the bottom in stages.

A single tatara is never used more than once, as it must be broken at the end of the smelting process in order to access the resulting tamahagane which forms at the bottom. For this reason, a tatara is always made of clay, which is then dried so it can be easily smashed later. After drying, it is fired from the bottom with a charcoal fire until an optimal temperature is reached before finally beginning the smelting process.

To begin smelting, ironsand is shoveled into the tatara every ten minutes. Charcoal is then added in between in order to supply the iron with vital carbon, so that the immense heat may harden them both into tamahagane over time. The mixture must also be turned over frequently as well. Each layer of iron-carbon mixture sinks to the bottom section of the tatara, known as the bed of fire, within about an hour each. This process is repeated and carried on for 72 hours, after which roughly 25 tons of ironsand are processed (1 ton of sand yields roughly 100 pounds of steel). As this is an ancient smelting method, it is truly old school - a team of skilled workers does this entirely by hand around the clock, making it a strenuous, exhausting, and sleepless procedure.

A defunct tatara in Shimane. Note the the series of holes along the bottom of the tub. These holes are connected through tubes to bellows on either side of the tatara, which blow air into the furnace to sustain the fire. Operating the tatara from start to finish required the combined efforts of about five to eight people.

After this process is done and all the iron has been entirely converted into tamahagane, it can start being collected. The tatara is subsequently demolished, and the still-hot accumulated raw steel is extracted from the bottom. The team must now inspect the tamahagane for impurities in order to judge whether the process was a success or not.

As mentioned before, tamahagane can be categorized into two grades: low-grade (akame satetsu) and high-grade (masa satetsu). A worker known as the murage decides how much of each type should be yielded during the process. Low-grade tamahagane is lacking in carbon and is thus a bit softer and grayish in color. The high-grade variety has a higher carbon content, and is thus harder, with a more lustrous appearance. It is important to use the right tamahagane so that the resulting sword is neither too soft nor too brittle.

Generally, the best tamahagane can be found along the sides of the tatara, where oxidation from the bellows has nurtured the steel to its best possible grade. After the chunks have been separated and evaluated, they are then shipped to various other facilities to be forged into various tools, most notably swords. The steel is now approaching its final stages of transformation, but there is still much to be done.

A collection of raw tamahagane chunks. The ones on the right are of a particularly higher grade, with a more tightly packed carbon arrangement. The ones in the middle have been re-smelted and have lost much of their carbonic integrity.

The various tamahagane chunks are heated by the swordsmith in a different furnace, and then repeatedly hammered into a collection of flat wafers. These fragments are then further scrutinized for purity, leaving only the best of the best sword steel behind. Even this far into the process, using steel chunks with improper carbon grades can result in an imperfect sword.

These wafers are then packed carefully atop the end of a smelting stick, covered in washi paper and a clay slurry to ensure adhesion, and then inserted into a forge at about 2,500 °F. This combines the steel wafers into a semi-molten chunk which can be hammered into different shapes. This hammering process further separates any imperfections from the tamahagane.

This hammering process also evenly distributes the carbon throughout the steel. It becomes clear that throughout the entire swordmaking process, from ironsand to blade, the material is rigorously stripped of impurities to make the final product as perfect as possible.

Tamahagane being hammered into a block shape. A joint is pierced into the middle of the steel, allowing it to be folded over. It is then hammered flat again, and then folded again. This process repeats until thousands of layers have been formed.

It is not solely the high-grade steel that must be made into the sword, however. As mentioned before, a sword that is too hard will chip and break very easily - not a very reliable weapon. Instead, some of that softer lower-grade steel from earlier is heated and then inserted in between the layers of high-carbon steel, resulting in a blade that is softer on the inside and harder on the outside. This soft steel core will give the sword good tensile strength and durability from breakage, while the harder exterior allows the blade to become very sharp and viable as a weapon.

Once the steel is hammered and flattened into a sword-like shape, just a few final steps are needed. The blade, which has not yet been hardened, is coated with a special clay paste - one side thin and the other thick.

This paste is meant to insulate the steel as it is hardened later. The coated blade is then inserted into the forge again, heated to a very precise temperature so as to not ruin the steel which, at this stage, has been so painstakingly folded and relieved of impurities. The final hardening process has to be just right.

The tamahagane can finally take on the familiar shape of a traditional katana. Even at this late stage, the steel is still hot and susceptible to further manipulation. Special clay paste is applied not long after this point.

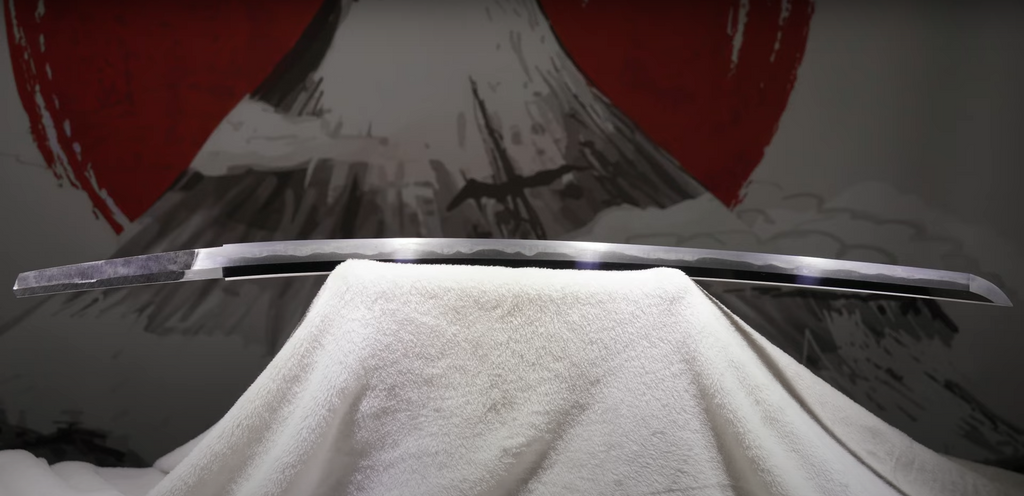

Once the blade has been sufficiently heated, only one major step remains: quenching. The blade is quickly submerged in water, which rapidly cools the steel. The cutting edge of the blade, which was coated in the thinner layer of clay paste, hardens immediately and packs its carbon more tightly. This makes it harder, allowing the edge to become extraordinarily sharp. Meanwhile, the back portion of the blade hardens more slowly, and thus becomes more durable. This differential heat application and carbon structure along either side of the blade creates the iconic light-and-dark wavy pattern across its length, known as a hamon.

The sword is then sharpened and polished, fitted with a handle and handguard known as a tsuba, in order to finally become a proper, finished sword. From the harvesting of ironsand to the completion of the blade, anywhere from fifteen to eighteen months have passed.

A hamon pattern. The lighter, higher-carbon steel comprises the sharp and precise cutting edge. The darker, softer steel provides a ductile sword body to prevent breakage. Underneath are countless steel layers for added strength.

Suffice it to say, this long and arduous swordmaking process was not discovered by accident. It took centuries to perfect, only held together by the passing down of techniques from generation to generation. Today, tamahagane steel is made only a few times a year, and only sold to a dwindling few licensed smiths as a way of preserving this aspect of Japanese culture.

Pieces of tamahagane at different stages of completion. Swordmaking is a process only certain talented and licensed individuals are certified to undertake.

And what about kitchen knives? Is tamahagane used in kitchen cutlery rather than solely for swords? Japan no longer engages in feudal sword combat, so naturally one might expect this steel to be put to use in other applications. However, the craft so far has been largely limited to swords as a way of honoring and preserving old Japanese culture - while they can still cut and maim, they are now simply works of art and mementos to an ages-old heritage. Even today, the katana persists as an iconic symbol of Japanese culture in both media and the real world, known far and wide beyond its island borders.

As a steel, tamahagane works extremely well in metal tools in addition to swords. Its hard, sharp edge resists dulling, yet the rest of the body is soft enough to make maintenance easy. It even has good protection against rusting - these properties truly make it something of a "goldilocks" steel.

So if tamahagane is so widely appreciated, why is it so hard to find kitchen knives made from it? The simple answer is that very few places in Japan produce tamahagane now. Due to the sheer scarcity of its production, as well as the fact that processing it is a long, difficult, and expensive venture, it is currently being prioritized solely for swords for the aforementioned cultural preservation. There is simply not enough to go around, and certainly not enough for the mass production of kitchen knives. To turn a profit at this scale, the knives would need to be quite simple to manufacture, which they are certainly not.

Yet, tamahagane chef’s knives do exist, but they are extremely rare. Only certain makers produce them, and yet they only comprise a small fraction of their usual inventory. And because they are so rare, they are immensely expensive, and are usually only sold on auction. Even in high-end Japanese knife stores, finding a tamahagane knife is virtually impossible.

A 260mm tamahagane gyuto chef’s knife made by Swedish-Japanese swordsmith Yasha Yukawa. The handle is made of blue-dyed snakeskin and a sycamore wood core, with a black titanium ferrule and dagger-style endcap.

However, something like the invisible hand of the market is not enough to stop the likes of us here at Seisuke Knife. We are aiming to acquire some genuine tamahagane knives in the future, so stay tuned for that!

If you enjoy this sort of content, please consider signing up for our newsletter. It’s a great way to stay alerted to new inventory items, sales, events, and more. Be sure to follow us on social media as well!

Comments (0)